# How to Tell When a Wire Rope Needs Replacement — 5 Critical Indicators

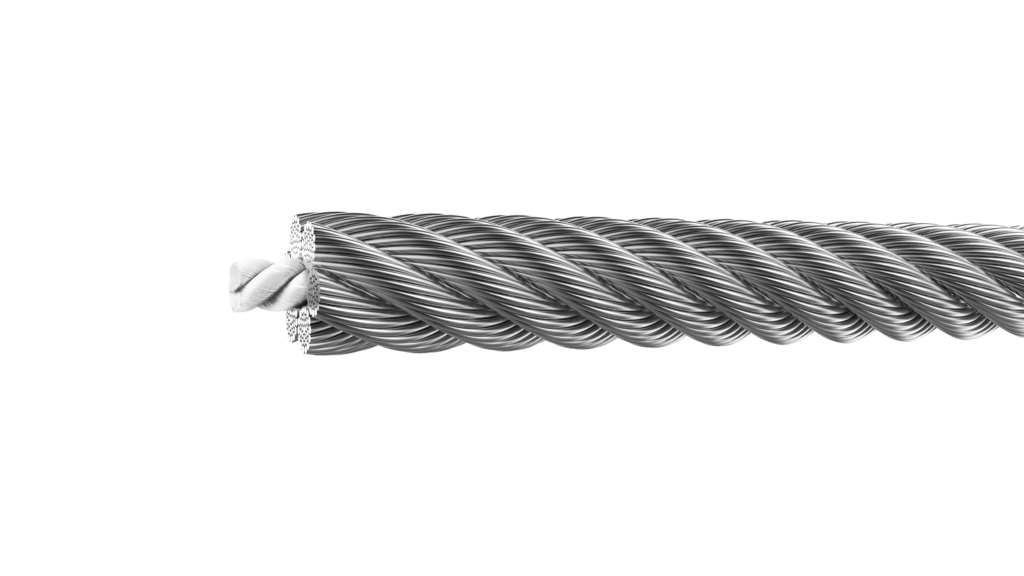

Wire ropes are essential components in cranes, elevators, and lifting systems. However, no rope lasts forever. Knowing when to replace a wire rope is crucial to prevent unexpected failures, costly downtime, or even serious accidents.

Here are **five critical indicators** that suggest it’s time to retire a wire rope—and how to spot them before it’s too late.

—

## 1. Excessive Broken Wires

One of the clearest signs of rope degradation is visible wire breakage.

### What to Check:

– Localized broken wires near terminations or high-bend areas

– Multiple breaks within one *lay length* (the length a strand takes to make one full turn around the rope)

### When to Replace:

– **6×19 ropes**: Replace if 6 or more wires are broken in one lay

– **8×19 ropes**: Replace if 8 or more wires are broken in one lay

– Clustering of broken wires in one area also increases failure risk

> Even a few broken wires near end fittings or on critical lifting ropes can require immediate action.

—

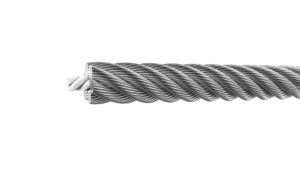

## 2. Reduction in Rope Diameter

As wire ropes wear internally, they often lose diameter. A decrease in rope thickness may indicate:

– Internal abrasion

– Core failure

– Wire fatigue or corrosion

### Inspection Tip:

Use a caliper to measure the rope at several points along its working length. Compare with the original nominal diameter.

### Replacement Threshold:

A reduction of **7–10%** typically indicates it’s unsafe to continue using the rope.

—

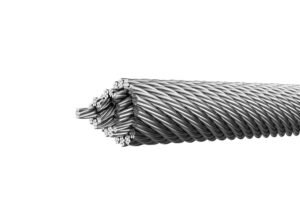

## 3. Corrosion — Visible or Hidden

Corrosion weakens steel, increases brittleness, and accelerates fatigue failure.

### Signs of Corrosion:

– Surface rust, reddish discoloration

– Rough feel, loss of flexibility

– Seepage of rust from inside the rope

### At-Risk Environments:

– Outdoor operations

– Marine/offshore use

– Chemical processing plants

Even if the rope appears intact, **internal corrosion** can critically reduce strength.

—

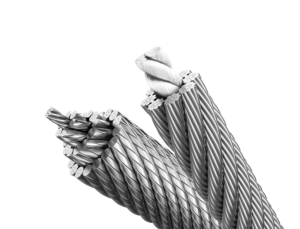

## 4. Rope Deformation and Distortion

Any abnormal change in the rope’s shape is a red flag. Common deformations include:

– **Kinks**

– **Birdcaging**

– **Core protrusion**

– **Flattening or crushing**

These conditions severely weaken the rope and typically **cannot be repaired**.

—

## 5. Abnormal Rope Elongation (Stretching)

All ropes stretch slightly under load. But if the rope becomes significantly longer than usual under the same working load, it indicates internal failure.

### Possible Causes:

– Collapsed core

– Internal fractures

– Excessive heat or fatigue

> Never ignore rope stretch—it’s often the final warning before failure.

—

## Always Follow Industry Standards

Use certified guidelines to make informed replacement decisions:

– **ISO 4309**

– **ASME B30.9**

– **EN 12385**

—

## Summary Table: When to Replace Wire Rope

| Condition | Replace If… |

|———————-|——————————————|

| Broken wires | ≥6 (6×19) or ≥8 (8×19) in one lay |

| Diameter reduction | >7–10% below original diameter |

| Corrosion | Significant rust or internal signs |

| Deformation | Any kinks, birdcaging, crushing |

| Rope elongation | Unusual stretch under normal load |

> If you’re unsure, replace early to prevent failure.