Lubrication isn’t just about keeping wire ropes shiny—it directly affects safety, performance, and longevity. Poor lubrication is one of the **top causes of wire rope failure** in the field.

—

## 1. Why Lubrication Is Essential

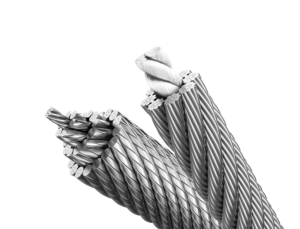

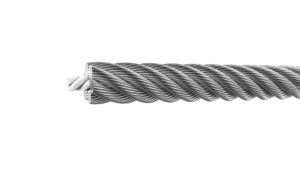

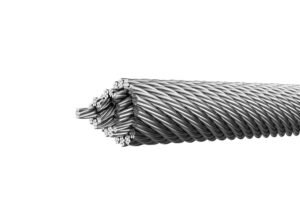

Wire ropes contain many steel wires twisted together. During operation, these wires generate internal friction, which can lead to:

– **Internal wear and fatigue**

– **Corrosion**

– **Loss of flexibility**

– **Premature failure**

Proper lubrication:

– Reduces wear

– Slows corrosion

– Maintains flexibility

– Extends lifespan

—

## 2. Types of Wire Rope Lubricants

### a. Penetrating Lubricants

– Low-viscosity oils

– Seep deep into the core

– Ideal for flexible or high-cycle ropes

### b. Coating Lubricants

– Thick, grease-like layer

– Protect against moisture, dust, and chemicals

– Best for marine or dusty environments

> Some products offer **dual action** for both penetration and surface protection.

—

## 3. When and How to Lubricate

### When to Lubricate:

– **Heavy-use ropes**: Every 1–2 months

– **Indoor/light use**: Every 3–6 months

– **After cleaning or rain**: Re-lubricate immediately

### How to Lubricate:

1. **Clean the rope** before applying

2. Use a **brush, spray, or pressure system**

3. **Rotate the rope** for full coverage

4. Avoid **over-lubrication**

—

## 4. Common Mistakes to Avoid

– ❌ Skipping lubrication entirely

– ❌ Using engine oil or motor grease

– ❌ Applying only to surface

– ❌ Not reapplying after rain or dust exposure

—

## 5. Choosing the Right Lubricant

A good lubricant should be:

– Water-resistant

– Compatible with steel and rope coatings

– Temperature stable

– Designed specifically for wire rope use

Refer to:

– **ISO 4309**

– **FEM 1.001**

– **Manufacturer specs**

—

## Conclusion

Lubrication is not just routine maintenance—it’s vital protection. With proper technique and scheduling, you can:

– Extend wire rope service life

– Improve safety

– Reduce equipment downtime

> A well-lubricated rope is a safe and cost-efficient rope.