As lifting technologies evolve, synthetic fiber ropes are emerging as alternatives to traditional steel wire ropes. While steel ropes remain dominant in elevators, cranes, and industrial hoisting, many engineers and operators are now evaluating whether switching to synthetic ropes makes sense.

This article compares the two rope types across key performance metrics and offers guidance on how to choose the right option for your application.

1. Overview of the Two Rope Types

Synthetic Ropes

Made from advanced polymers like:

UHMWPE (Ultra-High Molecular Weight Polyethylene)

Aramid (e.g. Kevlar®)

Polyester

Used in marine, offshore, elevator modernization, and specialized crane systems.

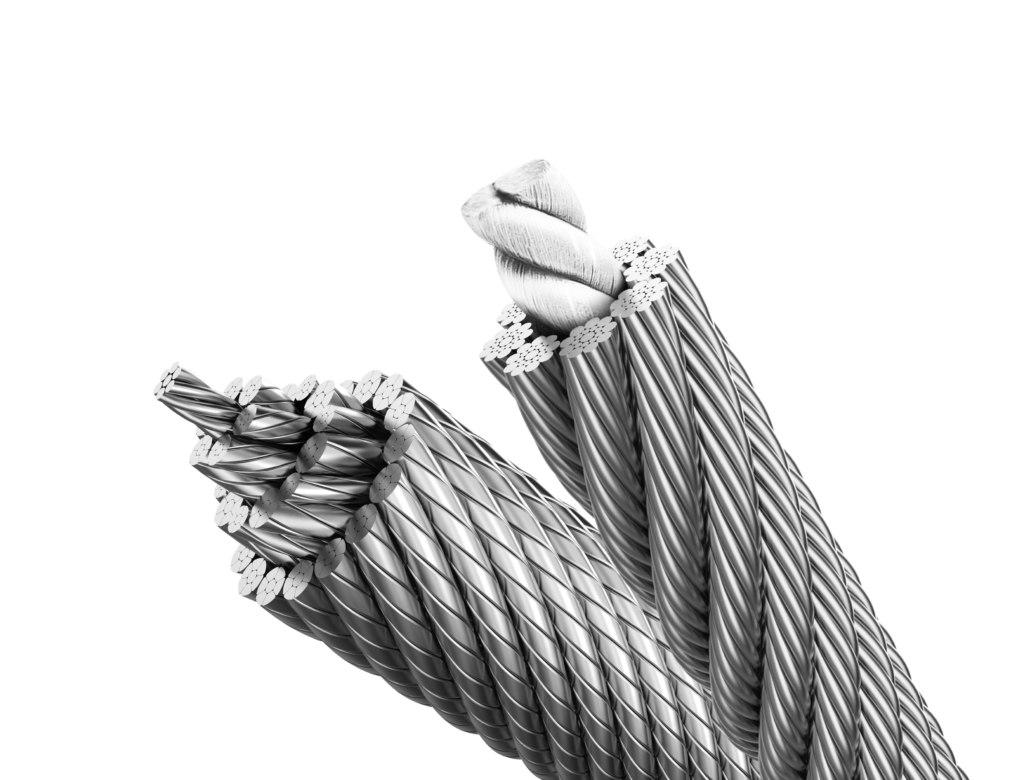

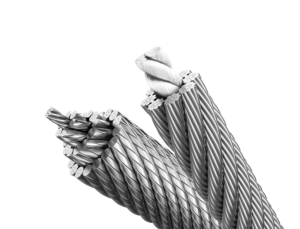

Steel Wire Ropes

Made from high-carbon steel wires, twisted into strands around a core.

Widely used in:

Elevators

Construction cranes

Mining hoists

Port equipment

2. Comparison Table

Property Steel Wire Rope Synthetic Rope

Tensile Strength Very high High (but lower than steel)

Weight Heavy 70–90% lighter

Flexibility Moderate Excellent

Fatigue Resistance Good Very high

Corrosion Resistance Moderate (needs lubrication) Excellent (non-corrosive)

UV/Heat Resistance Good Can degrade under UV or heat

Cost Lower initial cost Higher upfront cost

Inspection Method Visual + NDT tools Mostly visual

3. When to Use Steel Wire Rope

Steel is still the best option in many heavy-duty and safety-critical applications.

Recommended for:

High-load lifting (e.g. tower cranes, mining)

Friction elevators with high counterweights

Environments with high temperatures

Rotational stability and precise load control

Steel wire ropes are easier to inspect using magnetic and electromagnetic NDT tools, providing reliable safety tracking.

4. When to Use Synthetic Rope

Synthetic ropes offer significant advantages in weight-sensitive or corrosive environments.

Recommended for:

Elevator modernization where lighter ropes reduce motor load

Mobile cranes where quick deployment and re-spooling is needed

Offshore/marine projects exposed to saltwater

Environments where handling safety is important (no wire splinters)

Some companies, like Mitsubishi and Otis, have already adopted synthetic hoisting ropes in high-rise elevator systems to cut energy use and improve comfort.

5. Hybrid Options: The Best of Both Worlds

Some manufacturers now offer steel-synthetic hybrid ropes, such as:

Steel core with synthetic outer strands

Synthetic rope with embedded sensors or metal load strands

These offer:

Reduced weight

Improved fatigue performance

Compatibility with standard sheaves

6. Safety & Certification Considerations

Before switching to synthetic ropes:

Confirm certification under ISO 4344, ASME A17.1, or relevant local codes

Verify compatibility with existing sheaves, drums, and tension systems

Train staff on handling, inspection, and replacement criteria

Conclusion: Choose Based on Application, Not Just Technology

There’s no universal “better” rope type—only a better match for your specific application. Steel wire ropes remain the gold standard for heavy-duty, high-tension use, while synthetic ropes shine in lightweight, flexible, and corrosion-prone conditions.

Evaluate your priorities: strength, weight, safety, maintenance, and cost—and choose accordingly.