When it comes to elevator systems, motors and controllers often steal the spotlight. Yet behind every safe and smooth ride lies an equally critical component — the wire rope. As the main force-bearing element in traction elevators, elevator wire ropes must meet the highest standards in strength, flexibility, and reliability.

What Is an Elevator Wire Rope?

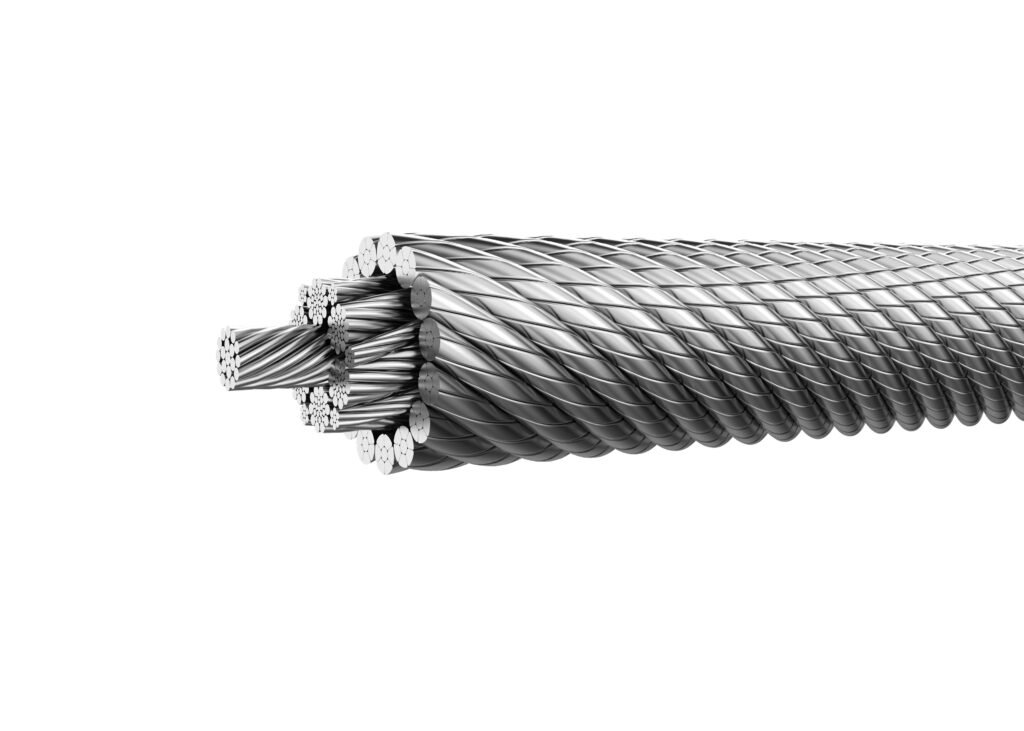

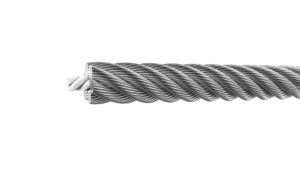

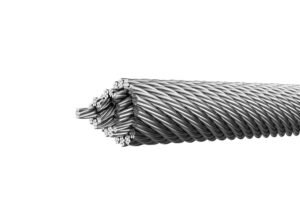

An elevator wire rope is a specially designed steel rope composed of multiple strands of high-strength steel wires twisted around a central core. This core can be a fiber core (FC) or an independent wire rope core (IWRC), depending on the application. The rope must balance tensile strength with flexibility to support the weight of the elevator and counterweight, while enduring thousands of lifting cycles.

Key Classifications

Elevator wire ropes come in several types based on function:

- Traction Ropes — The main load-bearing ropes that move the elevator car.

- Governor Ropes — Used in the overspeed governor safety system.

- Balance Ropes — Installed on high-rise elevators to balance tension below the car.

- Door Operator Ropes — Found in automatic elevator door systems.

Each rope has its own structure — such as 8×19S, 6×37M, or 6×19S — and is selected based on speed, load, building height, and safety requirements.

Choosing the Right Wire Rope

Several factors determine the proper rope for an elevator:

- Construction and Strand Type: Structures like 8×19S offer a good balance of flexibility and fatigue resistance.

- Rope Diameter: Must match the sheave size and elevator design.

- Tensile Strength: Typically ranges from 1320 MPa to 1770 MPa. Regional preferences vary — for example, Japan may use 1620 MPa ropes, while Europe favors 1570 MPa.

- Twist Direction: Right or left lay ropes should match machine requirements.

Why Quality Matters

A high-quality rope minimizes vibration, reduces wear on sheaves, and improves ride comfort. It also extends the service life of both the rope and the elevator system as a whole. Certified ropes should meet international standards such as ISO 4344 or GB/T 8903-2018, and pass strict tests including:

- Breaking force test

- Torsion and bending fatigue test

- Elongation and diameter reduction test

- Surface inspection and structure verification

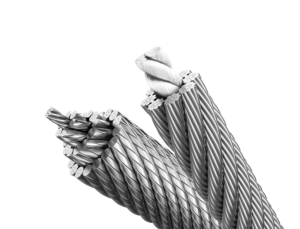

Maintenance and Replacement

Even the best rope requires proper maintenance. Regular inspection for broken wires, corrosion, diameter loss, or twisting is essential. Lubrication, tension adjustments, and environmental control all help extend rope life. Typically, ropes should be replaced when damage exceeds safe limits or when the service life recommended by the manufacturer ends.

Conclusion

Elevator wire ropes may be hidden from view, but they are critical to vertical mobility. Whether you’re an OEM, installer, or maintenance company, choosing and caring for the right rope ensures safer, smoother, and more efficient elevator operations. At [Your Company Name], we’re proud to offer certified, fully tested wire ropes tailored to your exact needs — because every ride starts with quality at the core.