Elevator wire ropes are critical components in vertical transportation systems, directly affecting safety, performance, and reliability. Understanding their structure, materials, and selection criteria is essential for engineers, procurement managers, and maintenance professionals.

1. What Are Elevator Wire Ropes?

Elevator wire ropes are specially designed steel cables used to lift and lower elevator cars. Unlike general-purpose wire ropes, elevator ropes are engineered to withstand repeated bending, tensile loads, and wear under high-cycle operation.

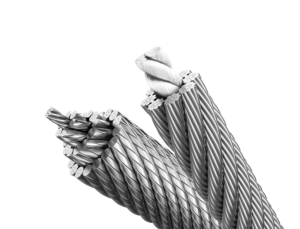

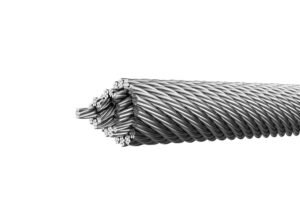

They usually consist of:

Strands: Typically 6 or 8 per rope

Wires per strand: Usually 19 to 25

Core: Either fiber core (FC), steel core (IWRC), or synthetic core (e.g., plastic impregnated)

2. Common Structures and Configurations

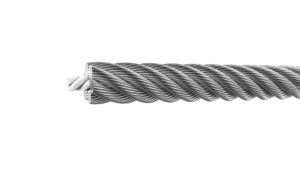

The most common constructions for elevator wire ropes include:

6×19S or 6×25FW + FC: Standard ropes used in many low- to mid-rise elevators

8×19S + IWRC: Higher flexibility, suitable for high-speed applications

8×19S + plastic core (PU/PE): Improved stability, corrosion resistance, and reduced internal wear

The rope structure should be chosen based on bending radius, elevator speed, and load requirements.

3. Materials Used

Wire ropes are generally made from:

High-carbon steel (galvanized or ungalvanized): Offers high tensile strength

Stainless steel: Used in corrosive environments (e.g., marine or chemical plants)

Plastic-coated or plastic-filled ropes: Enhance fatigue resistance and reduce noise

Tensile grades range from 1570 MPa to 1960 MPa depending on strength and flexibility needs.

4. How to Choose the Right Elevator Wire Rope

Key factors to consider include:

Elevator Speed:

Low speed (<1.75 m/s): Standard ropes suffice Medium to high speed (≥2.5 m/s): Requires enhanced fatigue-resistant ropes Rated Load: Heavier cars require thicker ropes or multiple falls Bending Cycles: Frequent bending over small sheaves requires high flexibility Rope Diameter: Must be compatible with sheave groove dimensions Environment: Corrosive environments need stainless steel or plastic-covered ropes Always refer to manufacturer specifications or international standards (e.g., ISO 4344, EN 12385-5) when selecting ropes. 5. Maintenance and Inspection Tips Regular inspection and lubrication are critical to extend the service life of elevator ropes. Look for: Broken wires Corrosion Flattening or bird-caging Rope elongation Uneven wear in grooves Proper lubrication (with penetrating rope lubricants) reduces friction and internal wear. 6. Conclusion Choosing the right elevator wire rope involves more than selecting a size or tensile grade. It's a matter of matching structure, material, and design to your specific application needs. With proper selection and maintenance, elevator wire ropes can provide years of safe, reliable service.