- Open : 9am - 5pm (Mon - Sat)

- NO.22-1 Jinka Road, Shenyang, China

- +86 18345156485

At VEGA, we offer over 30+ elevator wire rope models and 150+ crane wire rope models. Request a free quote from us today!

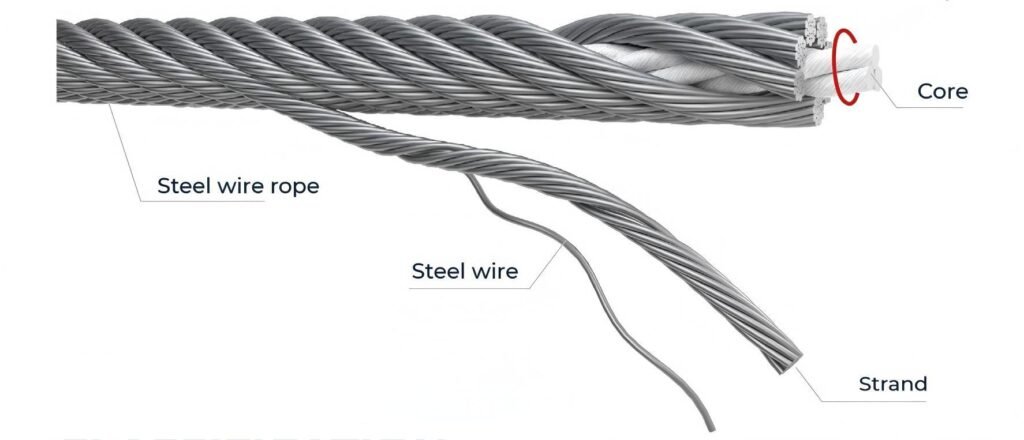

A wire rope is made of core, steel wire rope, steel wire and strand. Strands are formed by spirally twisting one or more layers of steel wires around a central steel wire, and the strands are spirally twisted around the core to form a steel wire rope.

And Elevator wire ropes typically range from 6mm to 38mm in diameter. Common specifications include 8mm, 10mm, 12mm, 13mm, and 16mm.

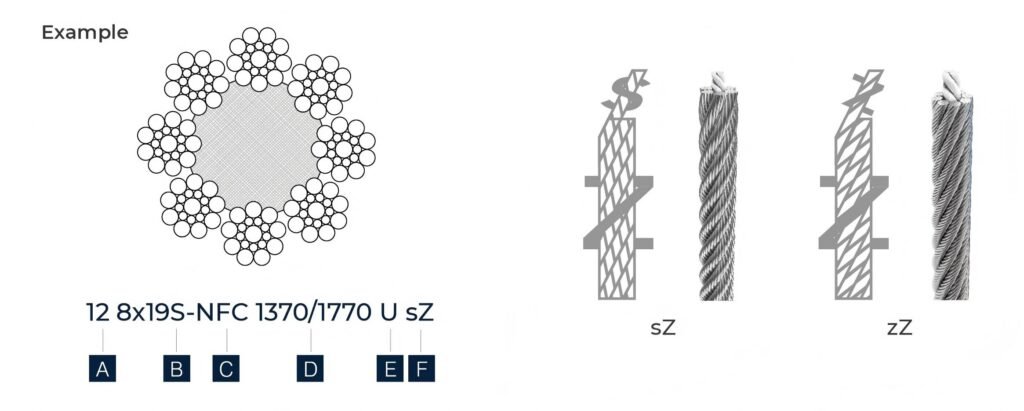

A: Diameter mm

B: Structure

Strand Construction Type

S – Seale

W – Warrington

F – Filler

WS – Warrington-Seale

C: Types of Cores

Fiber Core (FC):

NFC – Natural Fiber Core

SFC – Synthetic Fiber Core

GSF – Polymer Core

Steel Core (WC):

WSC – Wire Strand Core

IWRC – Independent Wire Rope Core

CSC – Mixed Core

PWRC – Parallel Laid Full Steel Rope

D:Tensile Strength Grade

E:Surface

U – Bright

A – Class A Galvanized

B – Class B Galvanized

AB – Class AB Galvanized

F:Lay Direction

sZ – Right Hand Regular Lay

zZ – Right Hand Lang Lay

zS – Left Hand Regular Lay

sS – Left Hand Lang Lay

Elevator wire ropes are categorized based on their specific function:

Traction Ropes:

For elevator speeds ≤ 2.0 m/s: 8×19S-NFC is recommended.

For better ride stability: 8×19S-GSF is preferred.

For high-speed elevators and tall buildings: 8×19S, 9×19S-IWRC, or CSC ropes are suitable.

Governor Ropes:

Recommended models: 6×19S-SFC or 8×19S-SFC

Balance Ropes:

Recommended models: 6×29F-SFC or 6×37M-SFC

Door Operator Ropes:

Recommended models: 6×7-WSC or 6×19M-WSC

The rope diameter is defined by the elevator’s design specifications and must match the factory configuration of sheaves and related components.。

Different regions have different preferences for tensile strength grades:

Europe, America, and China commonly use:

1370 / 1770 MPa, 1570 MPa, 1570 / 1770 MPa, 1770 MPa

Japan and South Korea often use:

1320 / 1770 MPa, 1620 / 1770 MPa, 1620 MPa

Our elevator steel wire ropes comply with key international and domestic standards such as ISO 4344:2022, ASME A17.6, ISO 4101:1983, and relevant Chinese GB standards. Additionally, our manufacturing process is certified under quality management systems like ISO 9001:2015, ensuring consistent product reliability and safety.

Before leaving the factory, every wire rope undergoes rigorous testing to verify tensile strength, diameter accuracy, lubrication quality, and fatigue resistance. These strict inspections guarantee that each rope meets or exceeds safety factors required for elevator operation worldwide.

The quality of the steel wire and the type of core (fiber core or steel core) significantly influence the price. Higher-grade steel with better tensile strength and durability costs more. For example, ropes made with high-strength steel or special corrosion-resistant coatings are priced higher

The diameter, construction (e.g., 8×19S+FC), and length directly affect the cost. Larger diameters or more complex constructions require more material and processing, increasing the price.

Advanced manufacturing techniques, strict quality control, and special equipment raise production costs, which reflect in the final price. More precise and durable ropes typically cost more due to these factors

Established brands with certifications and proven reliability often command higher prices because of their reputation and guaranteed quality.

Market demand fluctuations and raw material availability (like steel price changes) impact pricing. When steel prices rise or supply tightens, rope prices tend to increase accordingly.

Special coatings (galvanized, stainless steel) or treatments for corrosion resistance, wear resistance, or fire resistance add to the cost.

Transportation costs, packaging quality, and delivery timelines can also influence the final price, especially for large orders or urgent deliveries.

Inspect Regularly

Check the rope surface for broken wires, corrosion, deformation, or wear. Look for twists, kinks, or uneven tension. Measure rope diameter to monitor thinning from use.

Lubricate Properly

Clean the rope before applying lubricant. Use suitable lubricant at around 60°C for full penetration. Avoid over-lubrication, which can trap dust and cause buildup.

Control the Environment

Keep the operating environment dry, cool, and well-ventilated to prevent rust and heat-related damage.

Adjust Tension and Alignment

Ensure proper rope tension and check the condition of sheaves and drums. Misalignment or wear in these parts can reduce rope life.

Prevent Contamination and Damage

Keep ropes clean and free from dust. Avoid mechanical impact from tools or other equipment.

Visible Damage

Replace ropes if you find broken wires, severe corrosion, kinks, bird-caging, or flattening beyond acceptable safety limits.

Diameter Reduction

If the measured rope diameter has decreased significantly due to wear or corrosion, it indicates loss of strength and requires replacement.

Uneven Tension or Deformation

If ropes show signs of uneven tension, twisting, or permanent deformation that cannot be corrected, they should be replaced.

Usage Time Limit

Even without visible damage, ropes should be replaced after reaching their service life as recommended by the manufacturer or regulatory standards.

Frequent Elevator Malfunctions

Recurring elevator issues caused by rope slippage, noise, or vibration may signal internal rope damage and warrant replacement.

We offer basic knowledge and technical training related to the selection, usage, and maintenance of elevator wire ropes to support your team and business operations.

Can’t find the rope you need in our catalog? No problem. Our engineers can customize wire ropes based on your specific requirements — including tensile strength, twist direction, diameter, material, surface coating, and more.

From raw material inspection to in-process control and final product testing, we ensure that every rope leaving our factory is 100% qualified and meets international standards.

Our global technical team provides full-range support — from R&D to engineering, procurement, and sales — ensuring timely communication and reliable solutions tailored to your project needs.

At Vega Heavy, we transform complexity into simplicity! Just follow these three steps to get started today!

Provide specifications and any drawings or images of your required steel cables. Share the details of your project.

We'll craft a tailored solution and deliver a detailed quote within 24 hours, ensuring it meets your specific needs.

After your approval and deposit, we start mass production and manage all aspects of delivery.

WhatsApp us