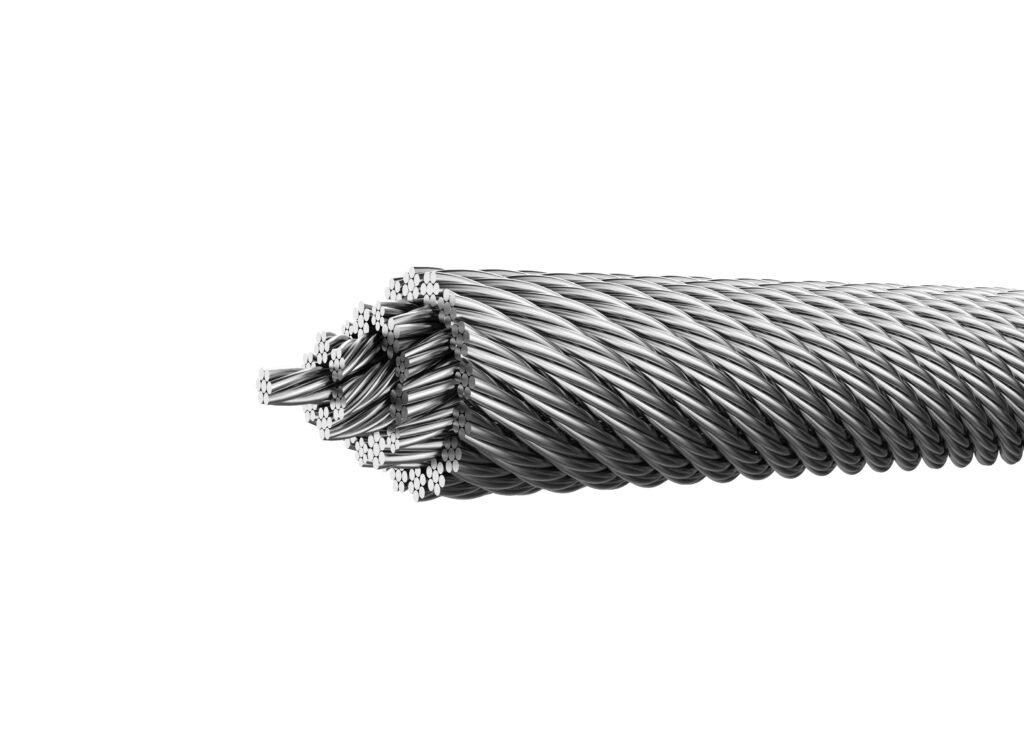

Crane wire ropes operate under extreme mechanical stress, often in harsh environments. Understanding the typical failure modes and implementing effective preventive measures is essential for maximizing safety and minimizing costly downtime.

1. Introduction: Why Wire Rope Failure Matters

In lifting operations, wire rope failure is one of the most serious risks. A single rope snap can lead to dropped loads, damaged equipment, and severe injury. That’s why regular inspection and understanding root causes of failure are critical.

2. Common Failure Modes in Crane Wire Ropes

Here are the most frequent ways crane ropes fail:

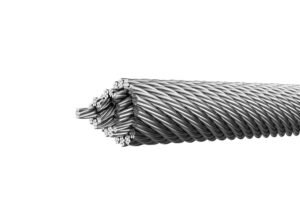

a. Wire Breakage due to Fatigue

Caused by repeated bending over drums and sheaves

Appears as broken outer wires, especially near rope terminations or points of bending

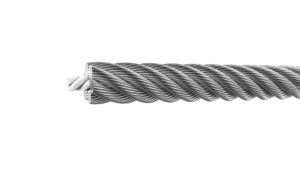

b. Abrasive Wear

Rope surface gradually wears down due to contact with sheaves, drums, or rough environments

Reduces diameter and weakens rope structure

c. Corrosion

Occurs in marine, chemical, or outdoor conditions without proper protection

Internal corrosion is especially dangerous because it’s hard to detect

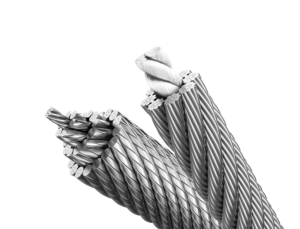

d. Core Collapse or Distortion

Happens when the rope is overloaded or improperly spooled

Results in kinks, birdcaging, or rope diameter deformation

e. Crushing

Caused by improper winding, tight drum grooves, or excessive load

Rope flattens or gets deformed, losing strength

3. Key Causes Behind These Failures

Overloading beyond the Safe Working Load (SWL)

Improper reeving or rope routing

Inadequate lubrication, leading to internal wear

Poor-quality sheaves or drums, causing uneven load distribution

Lack of regular inspection and maintenance

4. How to Prevent Wire Rope Failures

✅ Routine Inspection

Perform daily visual checks for broken wires, wear, corrosion

Conduct periodic in-depth inspections using calipers or magnetic NDT devices

✅ Proper Lubrication

Use rope-compatible lubricants that penetrate the core

Lubricate regularly depending on environmental conditions

✅ Correct Rope Handling

Avoid shock loading

Use proper tension during installation

Never drag ropes across rough surfaces

✅ Use of Quality Components

Ensure drums and sheaves are properly grooved and aligned

Replace worn components to avoid introducing stress concentrations

✅ Follow Retirement Criteria

According to standards like ISO 4309 or FEM 1.001, retire ropes with:

A certain number of broken wires per lay length

Significant diameter reduction

Core damage or distortion

5. Conclusion

Crane wire ropes are high-performance components that require strict attention to operation, inspection, and maintenance. By recognizing common failure modes and acting proactively, operators can greatly extend the service life of ropes and ensure a safer work environment.